Article: Choosing the Right Laser Machine: A Comprehensive Guide

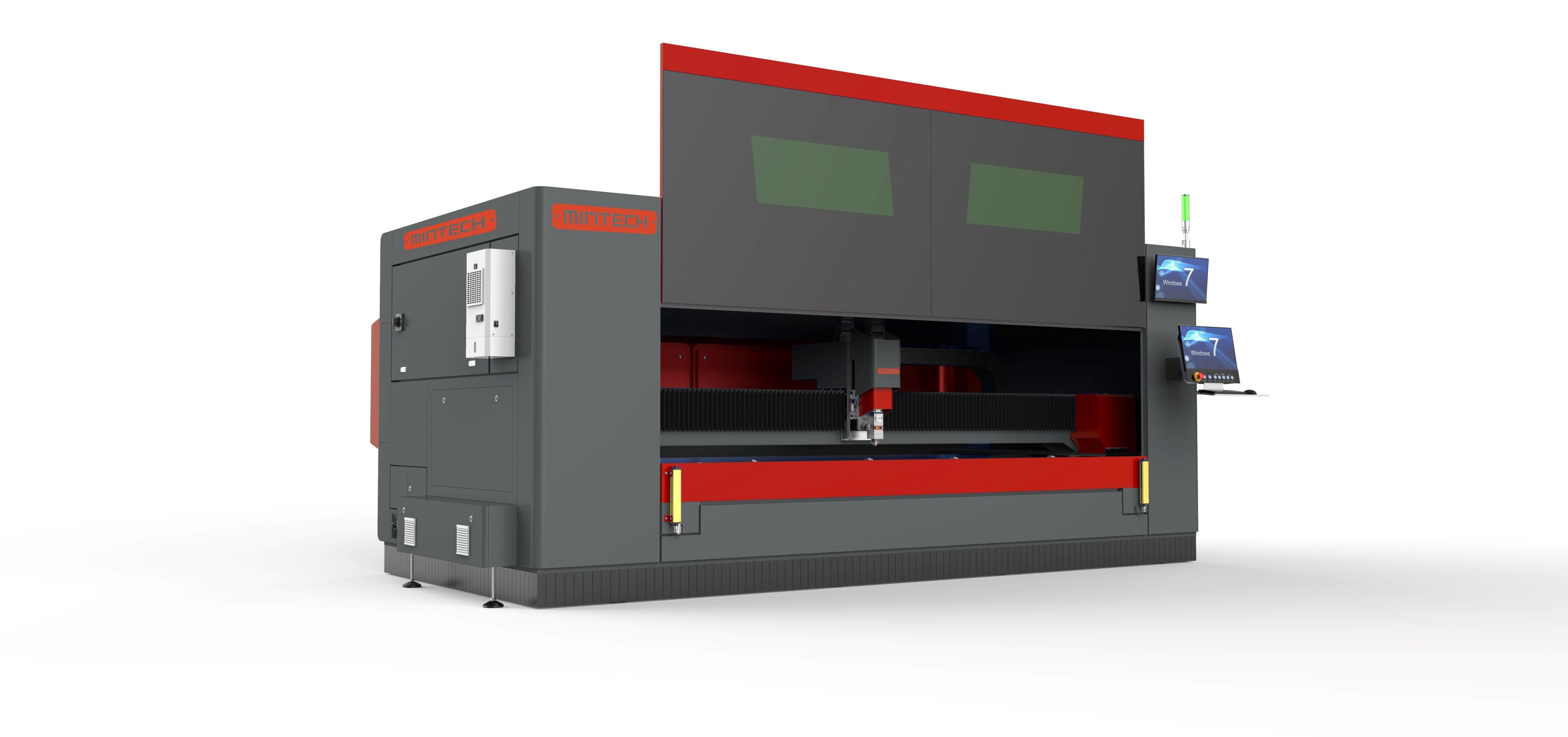

Choosing the Right Laser Machine: A Comprehensive Guide

Selecting the right laser machine can seem overwhelming with the variety of options available in the market. This guide will walk you through the key factors to consider when purchasing a laser machine, helping you make an informed decision tailored to your specific needs.

1. Laser Type

The type of laser is critical as it determines the materials and applications the machine can handle. The two most common types are:

-

CO2 Lasers: Ideal for non-metal materials such as acrylic, wood, leather, fabric, and certain plastics. Power options range from 20W to 600W, with higher wattages suited for cutting thicker materials.

-

Fiber Lasers: Best for cutting and engraving metals like stainless steel, aluminum, and brass. They are also suitable for marking plastics and other hard surfaces.

Understanding your material and application needs will guide you toward the appropriate laser type.

2. Tube Type

For CO2 lasers, the laser tube type significantly impacts performance and cost. The two main types are:

-

RF (Radio Frequency) Tubes:

-

Advantages: Longer lifespan (10,000–20,000 hours), excellent beam quality for precision, faster response time, and low maintenance.

-

Disadvantages: Higher upfront cost and lower power options.

-

Best For: Professional engraving and high-precision applications.

-

-

Glass Tubes:

-

Advantages: Lower cost, higher power availability (up to 200W+), and easy replacement.

-

Disadvantages: Shorter lifespan (1,500–8,000 hours), lower beam quality, and higher maintenance needs.

-

Best For: Budget-conscious users and applications requiring high power for cutting.

-

Choose the tube type based on your budget, precision needs, and usage frequency.

3. Motor and Transmission System

The motor and transmission system determine the machine’s speed, precision, and maintenance requirements.

-

Motors:

-

Stepper Motors: Affordable and reliable for basic engraving and cutting, but limited in speed and precision.

-

Servo Motors: High-speed and highly precise, suitable for professional-grade machines.

-

-

Transmission Systems:

-

Belt-Driven: Fast and lightweight, ideal for engraving but less precise.

-

Lead Screws: Precise and durable, best for detailed work at moderate speeds.

-

Ball Screws: Extremely precise and durable, suited for heavy-duty applications.

-

Rack-and-Pinion: High-speed and powerful, perfect for large-format cutting tasks.

-

Match the motor and transmission system to your desired balance of cost, precision, and speed.

4. Build Quality

The machine’s construction affects its durability and long-term performance. Look for:

-

Sturdy Frame: Essential for handling heavy use and material weight without deformation.

-

Cooling System: Ensure the machine has an efficient cooling system, such as a water chiller, to prevent overheating.

-

Quality Components: Assess the quality of mirrors, lenses, and other critical components.

Investing in a machine with high build quality minimizes downtime and maintenance costs over time.

5. Software and Compatibility

Ensure the machine is compatible with your workflow:

-

Software Compatibility: Look for machines that integrate with popular design tools like CorelDRAW, Adobe Illustrator, or AutoCAD.

-

File Formats: Confirm support for common file types such as .dxf, .ai, .svg, .jpg, and .png.

User-friendly software and broad compatibility streamline your operations and reduce learning curves.

6. Future Scalability

Think beyond your current needs and plan for the future:

-

Upgradability: Check if components like the laser tube or bed size can be upgraded as your business grows.

-

Workflow Integration: Ensure the machine fits seamlessly into your existing processes or production lines.

Investing in a scalable solution ensures long-term value and adaptability to evolving business requirements.

7. Applications and Use Cases

Consider what you’ll primarily use the laser for:

-

Engraving: Precision and detail are key; prioritize RF tubes and servo motors.

-

Cutting: Focus on power and durability; consider glass tubes and ball screws for high power and precision.

-

Combination of Both: Look for a machine that balances power and precision to handle diverse tasks.

Conclusion

Choosing the right laser machine requires balancing your budget, material requirements, precision needs, and long-term goals. By considering factors like laser type, tube type, motor system, build quality, software compatibility, and scalability, you can select a machine that best suits your business. If you have any questions or need personalized recommendations, feel free to reach out to us—we’re here to help!