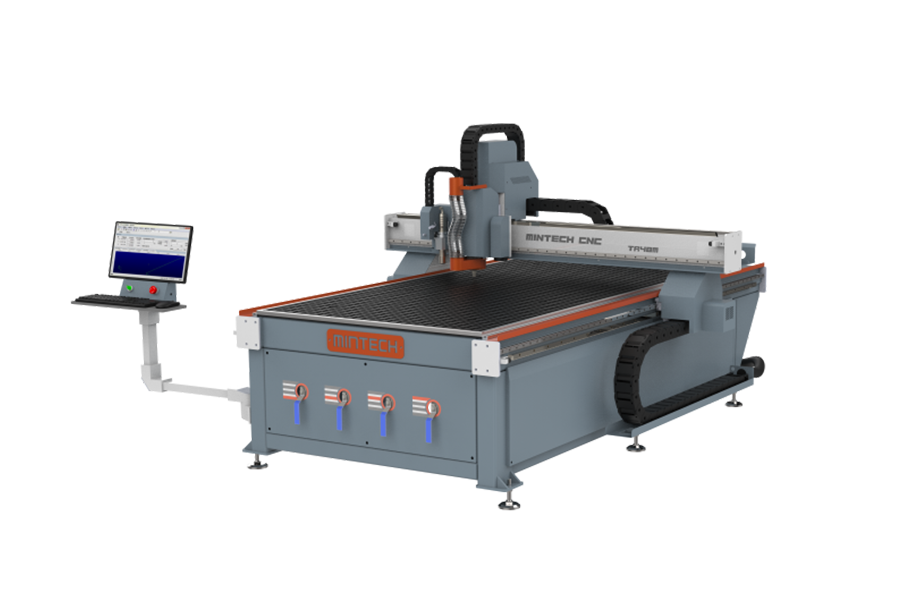

Acrylic Equipments

MPD Series

Visualization

Video

Content

File Formats:

G-code (.gcode, .nc): Machine-ready files for CNC operations.

DXF (.dxf): Standard for 2D designs and CAD drawings.

SVG (.svg), EPS (.eps), AI (.ai): Vector formats for detailed designs.

STEP/IGES (.step, .iges): 3D CAD formats for advanced machining.

CAM Software Compatibility:

Compatible with leading CAM software, including:

EnRoute

VCarve

Vectric Aspire

Fusion 360

Spindle

4kW ATC Oil Cooled

Linear Guide Rails

Hiwin or PMI linear guides.

Servo Motors

- Brand: Yaskawa, Delta, or Leadshine servo motors.

- Ensure smooth, accurate motion with high torque and low noise.

Transmission

Brand: TBI or THK ball screws.

Provide precise motion control, essential for accurate routing.

Vacuum Table

- High-strength vacuum table with multiple zones for efficient material hold-down during cutting.

- Suitable for various materials like wood, acrylic, aluminum, and composites.

Dust Collection System

- Integrated dust collection port for a clean working environment and improved machine lifespan.

Vacuum Zones

- 4 Zones Control for 4x8 ft

- 6 Zones Control for 5x10 ft

- Customizable

ATC

- Automatic Tool Change