Advantages of CO2 Laser Cutters

1

Clean Cuts with Minimal Waste

Produces smooth edges and reduces the need for post-processing.

Laser technology minimizes material wastage compared to traditional cutting tools.

2

Versatility

Works with a wide range of materials, including wood, acrylic, glass, leather, paper, and certain metals.

Perfect for industries like signage, crafting, manufacturing, and prototyping.

3

Customization and Flexibility

Ideal for personalized projects, one-off designs, and custom parts.

Easily integrates with CAD/CAM software for streamlined workflow.

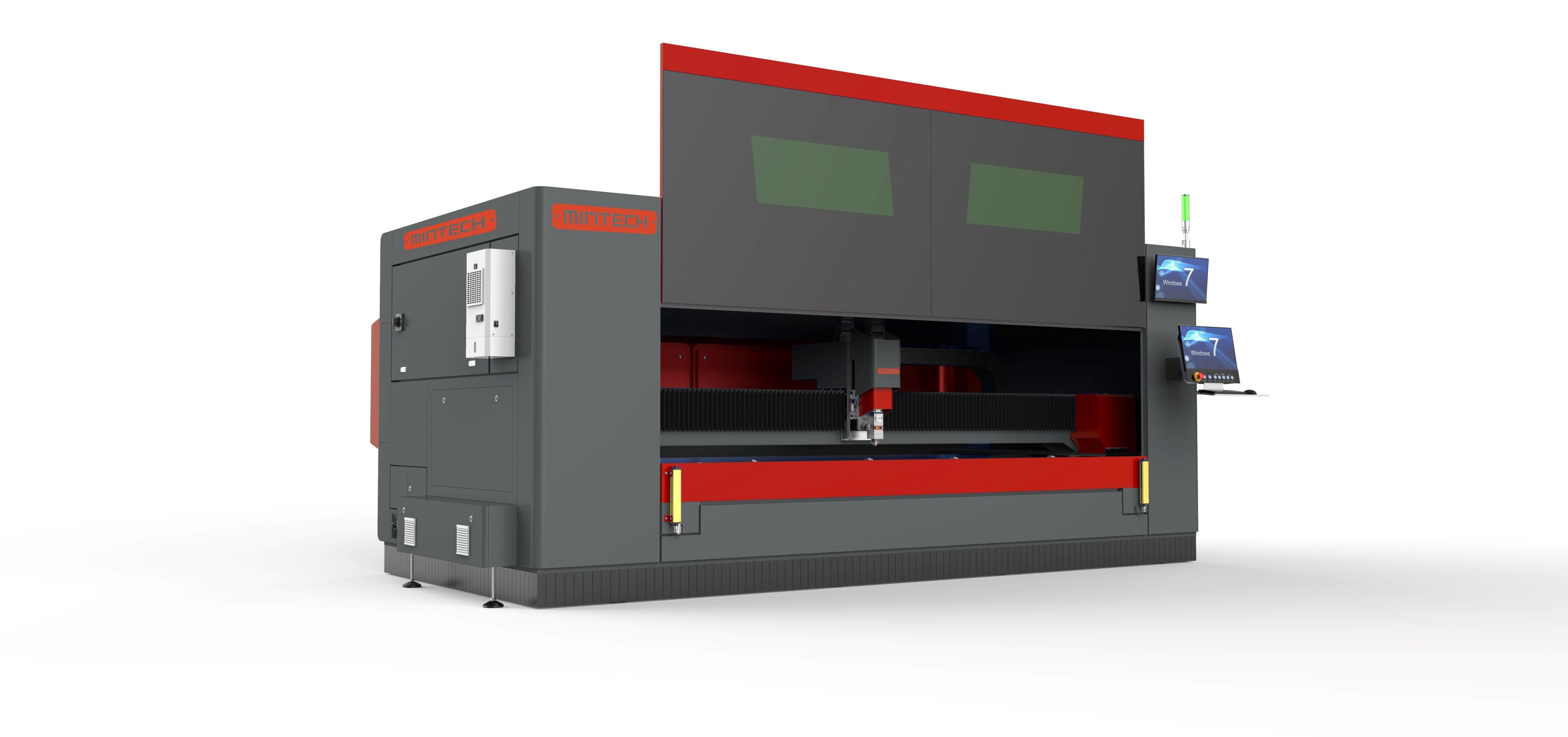

Choosing the Right Laser Machine

Make an informed decision with our expert guide on selecting the best laser machine for your needs.

CO2 Laser Cutting Capabilities

| Material | Cutting | Engraving |

|---|---|---|

| Metal | ||

| Aluminum | — | — |

| Aluminum, anodized | — | — |

| Chromium | — | — |

| Stainless steel | — | — |

| Metal, painted | — | ✓ |

| Plastic | ||

| Acrylonitrile butadiene styrene (ABS) | ✓ | ✓ |

| Acrylic/PMMA, i.e. Plexiglas® | ✓ | ✓ |

| Polyamide (PA) | ✓ | ✓ |

| Polyethylene (PE) | ✓ | ✓ |

| Polyurethane (PUR) | ✓ | ✓ |

| Miscellaneous | ||

| Wood | ✓ | ✓ |

| Acrylic (mirror) | ✓ | ✓ |

| Leather | ✓ | ✓ |

| Fabric | ✓ | ✓ |

| Cardboard | ✓ | ✓ |